The extreme sanctions imposed on Russia have hit industrial sectors the hardest, which have been almost entirely dependent on imports of high quality foreign made machinery for almost all of the last three decades since the fall of the Soviet Union.

The problem is that because of the timing of the collapse of the USSR, Russia missed out on two revolutions in precision tool making and is now hopelessly behind. Machine imports made up about half of all imports for decades.

China didn’t face this dislocation and has rapidly closed the gap with the West. China already leads in green tech development and production and recently overtook the US in EV manufacturing as well. In April it shocked the world with DeepSeek, an AI as powerful as ChatGPT, and then with the commercial production of a five-nanometre microchip that is as small as anything the US or Taiwan can produce that came entirely out of left field. And it was created entirely using Chinese machinery – a capacity that China was thought to be years away from. The chip, known as the Kirin 9000S, was developed by Huawei’s subsidiary HiSilicon, in partnership with Semiconductor Manufacturing International Corporation (SMIC).

Russia is still far away from this level of sophistication, but sanctions have accelerated its own development with simpler, but still important, technologies. Russian President Vladimir Putin boasted recently that sanctions have strengthened, not weakened, Russia by driving Russian innovation as companies invest and adapt to find domestically sourced solutions to their problems. And his boast is not entirely idle. While Russia is still generations away from producing its own competitive microchip, difficult-to-make technologies like high-efficiency gas turbines that have long been out of reach for domestic producers are starting to catch up with their Western peers.

From cheese to turbines

The classic example of this process is cheese. When Putin imposed agri-sanctions on EU imports in retaliation for the first round of Western sanctions on Russia following the annexation of Crimea in 2014, cheese disappeared from Russian supermarket shelves.

Cheese was almost entirely imported as European-made cheese was of a higher quality and lower price than anything Russian firms could make. But cut off from supplies completely, some Russian entrepreneurs threw themselves into the business and two years later Russia had a flourishing domestic cheese production sector, albeit still not quite as fine as their European analogues, but good enough to restock the shops.

Cheese is pretty easy to make, but gas turbines are another kettle of fish. Russian power firms like Silovye Mashiny (Power Machine), owned by oligarch Alexey Mordashov, is the leading producer of equipment for power stations, but it could never match the quality of Siemens high efficiency gas turbines that are at the heart of gas-fired power stations, despite heavy investment and a joint venture with Siemens pre-war.

Siemens came to virtually monopolise the gas turbine business in Russia. According to Siemens’ annual reports and press statements, it earned €1.3bn in revenues from Russia, or about 1% of its global sales but was also a strategically important market due to the long-term energy and infrastructure maintenance contracts.

Russia's dependence on Siemens was much more significant, as its high efficiency turbines have a notable economic impact because the fuel savings are on a scale that directly affects GDP figures. However, after the war in Ukraine began, Siemens suspended its operations in May 2022, leaving Russia without access to the German-made turbines it depends on.

That has just changed.

Specialists from the United Engine Corporation (UEC), part of the Rostec State Corporation, have completed testing of the second prototype of the new AL-41ST-25 industrial gas turbine engine. The engine was manufactured at UEC-UMPO in Ufa, Republic of Bashkortostan, that is almost as good as anything Siemens makes.

The AL-41ST-25 is a fully domestically produced industrial turbine designed to replace foreign equivalents in Russia's fuel and energy sector. It has a capacity of 25 MW and features enhanced efficiency, reliability and environmental sustainability.

The prototype consistently met its specified performance parameters in all operating modes, according to Rostec, matching the performance of the German-made equivalents.

It will now be installed at a compressor station in the Republic of Tatarstan, where the first prototype is already in operation as part of a gas pumping unit and has shown reliable performance, the Russian company said.

According to its designers, the turbine can outperform most existing domestic models in terms of efficiency, with a current rating of 39.1% and a potential for phased improvement to 40%. The AL-41ST-25 is the first Russian development to offer this combination of technical specifications.

On a side-by-side comparison, the Russian turbine still has some work to do. The AL-41ST-25 falls into the lower end of the medium industrial turbine power segment and is smaller than both of Siemens’ equivalent SGT-700 (33-34 MW) and SGT-800 (47.5-62 MW) in terms of output.

But the key breakthrough is that AL-41ST-25 is also most as efficient as the Siemens’ two turbines: 39.1% against 40% and 41.5% respectively.

Closing the gap with the German technology clears the way to replace every German turbine in every Russian power station and begin the process of weaning Russia off its dependency on imported foreign machinery as soon as production of the turbines can be scaled up. Its new found prowess in mechanical engineering means an assault on all sorts of higher quality machinery can also be launched. This process will take years to complete, but in this sense Putin is right: sanctions have provided the spur Russian innovation needed to accelerate innovation and upgrade its outdated technology.

Tech

China increasing its lead in robot technology use

China is consolidating its dominance in the global industrial robotics market, accounting for 41% of the world’s operational robot stock and more than half of all new installations in 2024, according to the International Federation of Robots.

The Iranian inventor that invented the floating shoes, has now built a propeller-less propulsion system ideal for flying taxis

Mohsen Bahmani is an Iranian-born mechanical engineer and a man with a dream. When he was just 17 years old, he made a pair of floating shoes that allow you to walk on water. Now he has built a propulsion system ideal for flying taxis.

_(1).jpg)

OpenAI to invest up to $25bn in Argentina under Milei incentive scheme

Artificial intelligence giant OpenAI and energy company Sur Energy have signed a letter of intent to develop a data centre hub in Argentina requiring investment of up to $25bn.

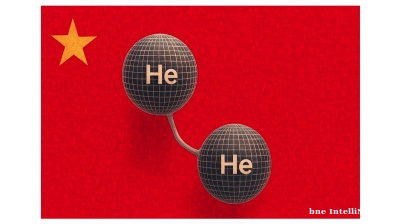

Helium was China's rare earth metals Achilles' heel

China has a devastating tool in its escalating trade war with the US: rare earth metals (REMs). Last week, Beijing announced new restrictive export controls on the export of anything with even a smidgen of Chinese-produced REMs.