Russia’s economic growth may well be in the toilet, but then that is probably the best time to get into the toilet paper business.

Nothing epitomises the failures of communism more than the old Soviet-era off-pink sandpaper-like toilet paper that was the hallmark of the old system. This toilet paper is still produced but alongside it has appeared the entire spectrum of multi-ply, scented pastel-coloured tissues that is probably the very first item the consumer upgrades to as soon as they get beyond mere surviving in post-Soviet Russia.

That makes quality toilet paper probably the most crisis-proof of all Russia’s goods and since bne IntelliNews visited with Mark Reznik, CEO of Syktyvkar Tissue Group (STG) in 2014, the company’s business has grown steadily, barely affected by the “silent crisis” of 2014, the collapse of retail sales and the deep devaluation of the ruble at the end of that year. However, plans to hold an IPO were scratched.

“The Russian tissue market has grown steadily in recent years: in the early 2000s, market behaviour was spasmodic (resulting in up to a 15% growth per year), then the growth rate dropped to 6% and has remained at that level until the present day,” VIYM, an alternative investment fund management firm and owner of Syktyvkar, said in a recent business update.

Despite the growth in sales Russians still consume a lot less toilet paper than their western peers. The average Russian tissue consumption currently fluctuates at around 3.8 kg per person per year whereas in Central Europe this figure is two times higher, at 8 kg per person per year, and the Western European it’s five times higher at 15 kg per person per year. But no one beats the Americans who consume a whopping 25 kg of tissue a head per annum, according to VIYM.

That leaves the business with a lot of upside even if it is only going to catch up with Central Europe, let alone the US.

“The forecasts are optimistic: over the next 12 years the market will more than double, to reach RUB180bn ($2.8bn) in retail sales. Over the past 15 years the leading players have increased capacity to satisfy existing market demand. Competition has not been intense and even non-core companies have started to invest in tissue production,” says VIYM.

And the business remains relatively concentrated, with just five companies accounting for 60% of the market: Essity (under Swedish holding SCA), Hayat Kimya, Syassky PPM, Syktyvkar Tissue Group, and Naberezhnochelninsky CPM.

And the business remains relatively concentrated, with just five companies accounting for 60% of the market: Essity (under Swedish holding SCA), Hayat Kimya, Syassky PPM, Syktyvkar Tissue Group, and Naberezhnochelninsky CPM.

Essity is the market leader with a 20% share of the market, but according to VIYM a new serious player is about to enter the market: the Arkhbum Tissue Group, a subsidiary of Arkhangelsk Pulp and Paper Mill, which plans to launch its own toilet and tissue paper production in 2019, with a production capacity of 70,000 tonnes of finished product per year, the equivalent of 10% of the total tissue produced in Russia in 2017.

With competition about to get a lot stiffer the smaller players, that account for 40% of the market collectively, must be looking to consolidate or merge. They don't have the technological or financial resources to protect their positions by taking the next step — producing the base paper themselves.

Syktyvkar Tissue Group was launched as a toilet paper production site at Syktyvkar Forest Enterprise in April 1987 and became a leading Soviet “brand” with its toilet paper called “56 Meters” that was very popular simply because it was not as bad as its competitors.

After the company was taken over by private investors in 2005 the new owners invested heavily in modern Italian machinery and improved the quality of the product again.

This was followed in 2006 with a production line for two-ply paper. The company established its own brand “Veiro” that was quickly recognised as one of the 100 Best Goods of Russia — a prestigious award at that time.

In 2007 a second paper-making machine was launched at the production site, which allowed the company to increase its capacity from 65 to 155 tones of product per day. In 2010 the first paper machine underwent a comprehensive restructuring and modernisation process.

In 2014 the company expanded again with a second production site in Rostov District, Yaroslavl Region. The site's paper producing machine was, and remains, the fastest in Russia and can produce 2,000 metres of loo paper per minute, VIYM boasts.

“Modern converting lines, some of which are unparalleled in Russia, allowed for the production of paper for the “Away From Home” segment – and that is how the brand “Veiro Professional” was launched,” VIYM says.

Today Syktyvkar Tissue Group has three paper-making machines with a total capacity of 85,000 tonnes per year and eight converting lines that produce sanitary-hygienic products from pulp and waste paper. With a total market share of 9% it is now the second largest producer after the market leader Essity.

Features

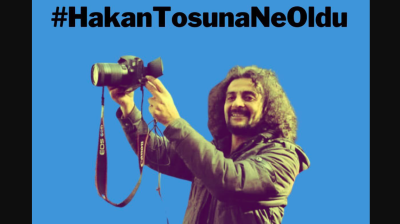

Journalist beaten to death in Istanbul as security conditions in Turkey rapidly deteriorate

Publisher, meanwhile, is shot in leg. Reporters regularly experience violence, judicial harassment and media lynching.

Agentic AI becomes South Korea’s next big tech battleground

As countries race to define their roles in the AI era, South Korea's tech giants are now embracing “agentic AI”, a next-generation form of AI that acts autonomously to complete goals, not just respond to commands.

Iran's capital Tehran showcases new "Virgin Mary" Metro station

Tehran's new Maryam metro station honours Virgin Mary with architecture blending Armenian and Iranian design elements in new push by Islamic Republic

Indonesia’s $80bn giant seawall

Indonesia’s ambition to build a colossal seawall along the northern coastline of Java has ignited both hope and heated debate. Valued at around $80bn, the project aims to safeguard the island’s coastal cities from tidal floods and erosion.