Something unexpected is happening in the region of Kaluga. Along with nearby Moscow, it is becoming a hub for Russia’s nascent alternative protein sector. Kaluga is already the location of a factory set up by Russian plant-based meat alternative pioneer Greenwise, and the Moscow and Kaluga region is now getting an incubator to nurture startups in the alternative protein space. Created by the Berlin-based Proveg incubator and the Association of Alternative Food Products Producers (AAFPP) – which in turn was set up by Greenwise’s founders – the incubator is a first for Russia and the CIS region.

In emerging Europe, as elsewhere in the world, awareness is dawning that to help fight climate change and feed the world’s growing population, there is a need to explore alternative sources of protein other than meat, seafood and dairy. Globally, alternative proteins from plants, insects and cultivated meat could make up as much as one-third to 40% of the market by 2050, but this depends on overcoming resistance to such products – they are still seen by many as the preference of cranky vegans rather than tasty food for the mainstream consumer – as well as developing alternative proteins in terms of taste, smell, look and texture.

“The trend in Russia is the same as in Europe and all the world in that the plant-based evolution is coming,” says Tim Ponomarev, co-founder of Greenwise, in an interview via Zoom. He believes the more conservative Russian market is around five to seven years behind Europe or the US – and that’s in big cities like Moscow and St Petersburg, not in rural areas where most people aren’t even aware of alternative proteins.

Having said that, things have moved forward a lot since Ponomarev and his partner Julia Marsel launched Greenwise in 2019 after two years of research. At that time there were only a couple of companies in the plant-based protein market in Russia, and products from international companies like Beyond Meat had yet to enter the market. “Today there are more than 30 companies in the area of plant-based meat alternatives, not only small startups but huge companies are investing billions of rubles in this area,” according to Ponomarev.

Looking at the reasons for this, he explains that it’s partly linked to the global hype around alternative proteins. The trend was accelerated as a result of the coronavirus (COVID-19) pandemic: “Raw materials are really expensive this year because of COVID and the broken logistics chains. In the meat market, margins are down because you have to buy soy or other fodder, feed the cow, kill the cow, make the meat… for plant-based protein you just have to buy the soy. We are cutting out the intermediate steps here and trying to create a product that is healthier, sticks to ethical standards and allows people to eat their favourite dishes without harming the environment.”

Greenwise, the startup launched by Ponomarev and Marsel, makes products such as plant-based patties which, its website says, “fully imitate the taste and aroma of beef”, plant-based cold cuts and plant-based filet. The company uses ecologically clean raw materials from Russia which it processes at its factory in the Kaluga region. Its products are carried by bricks and mortar retail chains like Vkusvill and Azbuka Vkusa and online marketplaces 4Fresh, Ozon, Wildberries and Yandex.Lavka.

As well as creating their own business, Ponomarev and Marsel saw that the market as a whole needed help to develop. “We are manufacturers but we also want to grow the market, create an ecosystem so alternative protein makes up not half [a percentage point] or 1% of the food industry, but 20%, 30% or 40%.” This involved setting up first an industry association, the AAFPP, then the incubator.

On top of this, says Ponomarev, who is a lawyer as well as having a deep knowledge of the food industry from his family’s processing business, “the main problem was the absence of any legal system regulating the market of alternative food products. We launched the first governmental standards for the manufacturing of this type of products, regulating what type of ingredients are allowed, what manufacturing processes, colourants, dyes, flavouring and so on.”

Finally, they are working on setting up a Russian version of the KitchenTown facilities, present in the US and Germany. “The problems we are solving [for other startups] right now are the problems we faced during our process of growth,” says Ponomarev. “One of the main ones was trying to go from the R&D and food creation processes to making the first batch of product and placing it on the market.” The existing alternatives – such as setting up a factory or paying a contract manufacturer or co-packer – tend to be too expensive and require prohibitively high volumes for small companies.

“There is a huge gap between R&D in a lab or kitchen and large-scale manufacturing – there is no intermediary. We suggested creating an intermediary: low-capacity manufacturing facilities where startups can produce a few thousand bottles or packs,” says Ponomarev, who sees this as “something like manufacturing co-working”. Talks are already underway with Russia’s ministries of trade and agriculture, as Ponomarev strongly believes this should be a product supported by the government. He points to the contrast between Russia and the US, where every month 50 to 100 startups are launched in the food tech space. This isn’t the case in Russia, “even though we have bright minds and people who are passionate about the area”.

Startups across emerging Europe

There are a growing number of innovative small companies working in the alternative protein sector – in areas from cultivated meat to edible insects – across the emerging Europe region. While there are numerous companies involved in cell-based protein in Western Europe, Bene Meat Technologies in the Czech Republic is currently the only company in the Central and Eastern Europe (CEE) region working on cultivated meat.

According to Bene Meat’s website, it is working on “changing the future of meat – meat without the need [for] killing animals or destroying the planet; meat that is healthy and accessible to all for an acceptable cost”. The company is currently developing technology for cultivated meat production without the use of animal components, starting with cultivated beef and later moving on to pork, chicken and other types of meat. “Cultivated meat originates by a controlled proliferation of animal cells. It is made using the same techniques of tissue engineering that are traditionally used in humane regenerative medicine,” the company says.

The company’s aim is to create a Czech biotechnological centre that will take its place among the global leaders in cultivated meat production technology. CEO Roman Kriz tells bne IntelliNews that Bene Meat is “mainly interested in the EU and US markets, plus Asia. The Czech market is not important in this perspective.”

In Poland, NapiFeryn BioTech has come up with a technology to extract food grade proteins from oilseeds, with a focus on rapeseed, which is widely grown in Poland. The company, one of European food innovation initiative EIT Food’s RisingFoodStars, believes rapeseed protein will become increasingly important. It aims to have least 5% of global rapeseed production processed with its technology. Initially, it is focused on the domestic market, but plans to expand to other countries where rapeseed is produced on a large scale, including Australia, Canada, China, France, Germany, India, the UK and the US.

Then there is Slovenia’s Juicy Marbles, a producer of meat-free steaks which says their fat structure is similar to prime grade cuts. In fact, the company’s website says it “analysed all parameters of animal meat and found some key features to improve” before producing the steaks on what it dubbed its Meat-o-Matic 9000™ machine.

Aside from Greenwise, among the other startups in Russia are neMyaso, 3D Bioprinting Solutions, which has been working with fast food retailer KFC to “print” meat for chicken nuggets using chicken cells and plant material, and Welldone, which recently secured $1.5mn from Lever VC, the venture capital arm of agroindustrial major GrainRus, and Phystech Ventures, a fund launched by a top Moscow science institute.

Then there are the companies exploring the field of edible insects, including Lithuania’s Crickets.lt, which incorporates crickets into high protein bars, “cricket cookies” and crackers, as well as selling frozen crickets and cricket powder for cooks to use in their own ways. Another is the Czech Republic’s Terraz, which has created what it calls Pasta of the Future, such as Cricket Tagliatelle, as well as pasta with more traditional proteins such as red lentils or spirulina.

The big guys are interested

Serbia’s Sojaprotein, the largest producer of plant-based protein in southern Europe, was recently acquired by ADM, the creator of the soy vegetable burger. Set up in 1997, Sojaprotein sells non-GMO vegetable protein ingredients in 65 countries; customers include companies in the meat alternative, confectionary, protein bar, pharmaceutical, pet food and animal feed segments.

The deal will expand ADM’s capacity to meet fast-growing global demand for plant-based proteins, the company said. “Today, alternative proteins represent one of our core growth platforms, and as this $10bn global industry grows to $30bn over the next decade, we are investing to expand our unparalleled capabilities,” according to Leticia Goncalves, ADM’s president of Global Foods. In Europe, added Goncalves, demand is growing among customers “who prioritise locally sourced, non-GMO ingredients in their food and beverages”.

The deal follows other investments by ADM into alternative proteins, including a soy protein complex in Brazil and a pea protein plant in North Dakota.

It’s not just the companies specialised in this segment that are investing. Major international food groups including Nestle and Cargill have done the same, as have meat production giants such as Tyson Foods and Smithfield Foods of the US, BRF, JBS and Marfig of Brazil, and many others.

Why go alternative?

Climate change, demand for food for a growing global population, ethical concerns about factory farming and an interest in healthy eating are all factors driving demand for alternative proteins.

A 2021 report from Boston Consulting Group (BCG), ‘Food for Thought: The Protein Transformation’ presents data showing that in 2020 people ate 574mn tonnes of meat, seafood, dairy and eggs, or almost 75 kilograms per person, an amount that is steadily increasing, especially in developing countries, as their populations get richer and disposable income increases.

At the same time, "alternative proteins have morphed in just the past few years from a niche product to a mainstream phenomenon,” says the report. Already, it points to the widespread offering of plant-based meats at fast-food restaurants, growing use of plant-based milk and the serving of meat grown from animal cells in restaurants in Singapore and Israel. BCG forecasts a $290bn market by 2035, with consequences including freeing up an area of land the size of the UK from agriculture, a water use reduction of 39bn cubic metres, 50bn fewer chickens in factory farms and a 1bn tonne fall in carbon dioxide emissions.

“What we see today is only the beginning of the protein transformation … By 2035, after alternative proteins reach full parity in taste, texture and price with conventional animal proteins, 11% of all the meat, seafood, eggs and dairy eaten around the globe is very likely to be alternative. With a push from regulators and step changes in technology, that number could reach 22% in 2035. By then, Europe and North America will have reached the point of ‘peak meat’, and consumption of animal proteins will begin to decline,” says the report.

“Cultivated meat production has all the conditions to be more effective source of nutrition than regular meat. And when you add ethical, health and environmental aspects … we have no doubt that most of the meat consumed in twenty years from now will be from bioreactors, not animals,” forecasts Bene Meat’s Kriz.

What the industry is aiming for is for alternative proteins to be a real alternative to meat for the mass market in terms of both eating experience and price. BCG forecasts: “Consumers will soon be able to make nine out of ten of the world’s most popular dishes – especially those using less-structured meat, such as ground beef – with reasonably priced alternative proteins. However, it warns that a shift from animal proteins to alternatives will depend on advances in technology that would make alternative proteins competitive with traditional ones on taste, texture and price.”

This was also raised by industry insiders Kriz and Ponomarev. The Bene Meat CEO notes that as most of the products on the market in the Czech Republic are in the premium price segment, meaning they are far from being a real alternative to meat. Commenting on the challenges faced by the sector to bne IntelliNews, he says: “We strongly believe it is a question of the pricing and nutrition quality. Not many people want to spend money on alternatives based on plants when they can eat the plants directly. That is why our target production price of the cultivated beef is around €4 per kilogram. Once we reach this price, the cultivated meat will overtake most of the meat market.”

Aside from price, for Ponomarev it’s also a question of education, which is required in Russia where there is little awareness of alternative proteins, especially outside the main cities. As well as working with influencers and the media, one of their tactics was to put up Russia’s first plant-based meat billboards at a bus stop, much to the confusion of passersby.

He insists it’s not a question of trying to convert people to become “radical vegans” but of presenting an option. “If they like it, that’s good; if they don’t, it’s something for us to work on,” he says. He believes it’s harder to quit eating a favourite food than to stop drinking or smoking because food habits are the strongest, many stemming back to childhood; hence the Russian expression “mother’s food”. “It’s difficult to cut this connection,” he acknowledges. However, he says, with products on the market now closely imitating meat, there’s “no need to change the person, we just need to change the product, we are changing meat, not man.”

Features

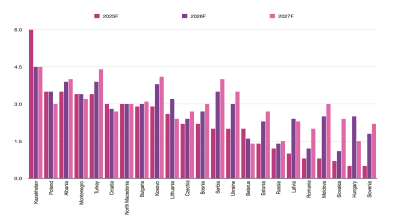

Emerging Europe’s growth holds up but risks loom, says wiiw

Fiscal fragility, weakening industrial demand from Germany, and the prolonged fallout from Russia’s war in Ukraine threaten to undermine growth momentum in parts of the region.

The man who sank Iran's Ayandeh Bank

Ali Ansari built an empire from steel pipes to Iran's largest shopping centre before his bank collapsed with $503mn in losses, operating what regulators described as a Ponzi scheme that poisoned Iran's banking sector.

Andaman gas find signals fresh momentum in India’s deepwater exploration

India’s latest gas discovery in the under-explored Andaman-Nicobar Basin could become a turning point for the country’s domestic upstream production and energy security

The fall of Azerbaijan's Grey Cardinal

Ramiz Mehdiyev served as Azerbaijan's Presidential Administration head for 24 consecutive years, making him arguably the most powerful unelected official in post-Soviet Azerbaijan until his dramatic fall from grace.