The headline seasonally adjusted IHS Markit Russia Manufacturing PMI recovery slowed in March, but still registered 51.1, down slightly from 51.5 in February, but still above the 50 no-change mark.

“The March PMI data signalled another marginal improvement in operating conditions across the Russian manufacturing sector. The overall expansion slowed slightly, however, as the upturns in output and client demand softened,” IHS Markit said in a press release on April 1. “Severe supply chain disruptions continued to impact goods producers, as raw material shortages led to marked hikes in input costs and a further decrease in purchasing activity. At the same time, selling prices rose at the second-fastest pace for over six years as firms sought to partially pass on higher costs.”

Contributing to the softer overall upturn was a softer increase in production among goods producers, Markit reports. Although firms linked the increase in output to a sustained rise in client demand, firms noted a loss of growth momentum amid constraints on production imposed by supplier price hikes and raw material shortages.

Russia’s economic recovery is underway and although the economy saw a milder contraction in 2020 than most analysts were forecasting after the coronacrisis broke out, this year the recovery will be milder than in most other large economies due to Russia’s lingering structural problems.

“New orders increased for the third successive month in March, albeit at the slowest pace in the aforementioned sequence of expansion. The marginal rise was reportedly linked to greater demand from existing clients. In contrast, new export orders fell further. The rate of contraction softened from February's solid decline, however,” Markit reports. “Meanwhile, vendor performance deteriorated to the greatest extent since May 2020 at the end of the first quarter.”

The aftereffects of the coronacrisis continue to impact companies as supply chains remain affected. Longer lead times were commonly attributed to severe transportation delays, supplier capacity constraints and raw material shortages. The extent to which delivery times lengthened was also one of the most marked in the over 23-year series history, Markit said.

Inflation pressures have also returned, causing the Central Bank of Russia (CBR) to hike rates by a surprise 25bp in March. Manufacturers also report rising price pressures, says Markit, “[and] although the rate of cost inflation eased to a five-month low, it was well above the series trend.”

In response, firms continued to raise their selling prices in March, although economists say that inflation may have peaked in February or March.

“The increase in charges was widely linked to the pass-through of higher costs to clients. The rate of output price inflation was slightly softer than that seen in February, but was nonetheless the second-sharpest for over six years,” says Markit.

Supply chain disruptions also impacted stock control at manufacturing firms. Companies registered a renewed drop in input buying amid supplier price hikes. As a result, pre- and post-production inventories dwindled amid challenges replenishing stocks, with the latter falling at its quickest rate since June 2020.

Softer new order also growth led to a further decline in backlogs of work. The level of outstanding business fell solidly amid sufficient capacity to process incoming new work. Subsequently, employment was broadly unchanged in March, bringing to an end a two-month sequence of expansion.

Finally, output expectations at manufacturing firms softened slightly, but were upbeat overall. The degree of optimism was the second-highest since January 2020 amid hopes of an uptick in client demand and planned investment.

Data

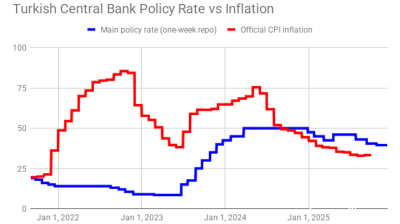

Turkey's central bank remains cautious, delivers 100bp rate cut

Decision comes on eve of next hearing in trial that could dislodge leadership of opposition CHP party.

Polish retail sales return to solid growth in September

Polish retail sales grew 6.4% year on year in constant prices in September, picking up from a 3.1% y/y rise in August, the statistics office GUS said.

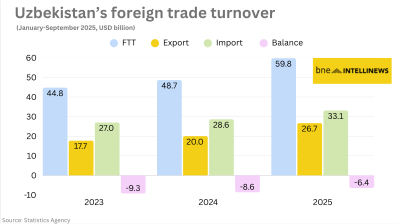

Uzbekistan’s nine-month foreign trade nears $60bn

Export growth of 33% and import expansion of 16% y/y produce $6.4bn deficit.

Hungary’s central bank leaves rates unchanged

National Bank of Hungary expects inflation to fall back into the tolerance band by early 2026, with the 3% target sustainably achievable in early 2027 under the current strict policy settings.